Renison Tin Operation

(MLX 50%)

Metals X has a 50% equity interest in the Renison Tin Operation in Tasmania (Renison) through its 50% stake in the Bluestone Mines Tasmania Joint Venture (BMTJV).

Renison is the largest tin producer in Australia, one of the world’s largest and highest-grade tin mines and through the Metals X equity interest, one of the few publicly held tin projects in the world.

Renison is located on the west coast of Tasmania, approximately 15km north-east of Zeehan. Mining at Renison has made important contributions to the regional and state economy of Tasmania for over 50 years. Renison is a major employer on the West Coast of Tasmania, with approximately 50% of employees living locally and 50% in the Renison camp in Zeehan.

History

- 1890: Discovery by George Renison Bell (alluvial cassiterite) and commencement of production.

- 1958: Acquisition of Renison by the Mount Lyell Mining and Railway Company Limited – commencement of modern era of Renison.

- 1980’s-90’s: Mine operated under Renison Goldfields Consolidated (RGC).

- 1998: Acquisition of Renison by Murchison United.

- 2004: Acquisition of Renison and Mt Bischoff by Bluestone Tin Limited, refurbishment program completed and commissioning of operations at Renison.

- 2005: Suspension of operations at Renison due to low tin prices.

- 2006: Merger of Bluestone Tin Limited and Metals Exploration Ltd to form Metals X Limited.

- 2008: Resumption of mining at Renison and at Mt Bischoff.

- 2009: Resumption of operation of processing plant.

- 2009: Feasibility Study completed for Renison Tailings Retreatment Project.

- 2009: Sale of 50% of Renison to Yunnan Tin Group of China and formation of Bluestone Mines Tasmania Joint Venture.

- 2010: Closure of Mt Bischoff mining operations.

- 2018: Construction and commissioning of new 3-stage crushing circuit and ore sorter.

Geology

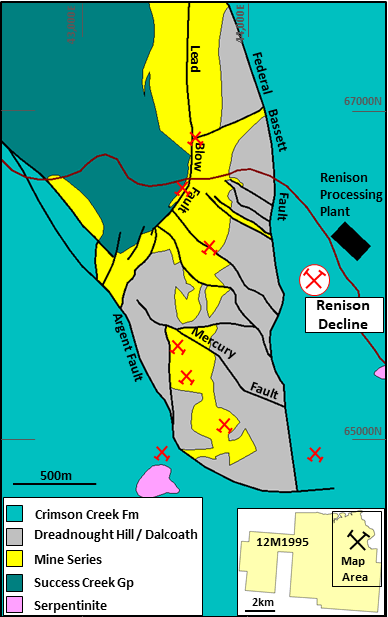

The Renison deposit is hosted by a thick late Neoproterozoic to Palaeozoic sedimentary and volcanic sequences of the Success Creek Group and Crimson Creek Formation which were deposited within the Dundas Trough between two Neoproterozoic blocks; the Tyennan and Rocky Cape massifs to the east and west respectively.

The Renison deposit is hosted by supratidal to intertidal dolomitic and siliciclastic sediments of the Renison Mine Sequence which comprises the upper ~80m of the Success Creek Group and the lower ~60m of the overlying Crimson Creek Formation. The Renison Mine Sequence ranges from 50 to 200m in thickness, but is in general around 140m, with individual cherts and carbonates being from 10 to 20m thick. The primary carbonates are well bedded manganiferous dolomite or pistomesite.

The Renison Mine Sequence has been intruded by the Devonian Pine Hill Granite which is interpreted to have likely been the source of the hydrothermal fluids responsible for carbonate replacement tin mineralisation.

The deposit occurs on the NE limb of the broad, SE plunging, Renison Bell Anticline, which constitutes a horst block bounded to the NE by the NW-SE trending, 60 to 85°NE dipping Federal-Bassett Fault, to the SW by the subparallel Blow Fault and to the south by the east-west striking Argent fault. The horst is ~700m to 1km wide and 3km long.

Mineralisation at Renison occurs in three main forms:

- Stratabound massive sulphide orebodies,

- Strata-fault massive sulphide orebodies, and

- fault enclosed massive sulphides and vein clusters.

Mineralisation comprises tin, almost solely as fine grained cassiterite, commonly associated with significant sulphide development dominated by 65-70% pyrrhotite and variable arsenopyrite and pyrite. Chalcopyrite is a widespread trace mineral while galena, sphalerite and stannite are encountered sporadically.

Mining & Processing

Processing of ore includes three stage crushing, ore sorting (XRF), primary grind, copper flotation and cassiterite flotation in addition to concentration. The tin ore is subject to fine grinding, magnetic separation, and tin flotation processes.

Tin is recovered using LIMS and WHIMS magnetic separation methods. Gravity tailings are ground to minimise the cassiterite content. Magnetic separation, acid leaching and enhanced gravity separation are performed to enhance the tin flotation feed.

Cassiterite minerals are separated from the hematite using a concentrate cutter. C2000 Falcon centrifugal concentrators in operation at the plant are capable of recovering concentrate particles at a rate of 60t per hour.

Infrastructure

Renison is located approximately 15km northeast of Zeehan on the Murchison Highway, with access to fully sealed roads to the Burnie port. The site is serviced with 44 kV regional power distribution from the Rosebery Substation.

The operation has a modern 100-person camp in Zeehan.

Responsible Production of Tin

Metals X is committed to the responsible and sustainable mining of tin and is a member of International Tin Association.

WATCH THE RENISON MOVIES

Renison Area 5 – June 2020

The Renison Tin Operation – February 2014